Our range of lubricating greases

With our wide range of lubricating greases, we meet the challenges of all branches of industry. Our portfolio includes a wide range of high-quality lubricating greases for professional use, which are suitable for different operating conditions, areas of application and branches of industry: such as mechanical engineering, packaging or heavy industry.

Our TUNGREASE portfolio includes the following greases

- High-temperature greases

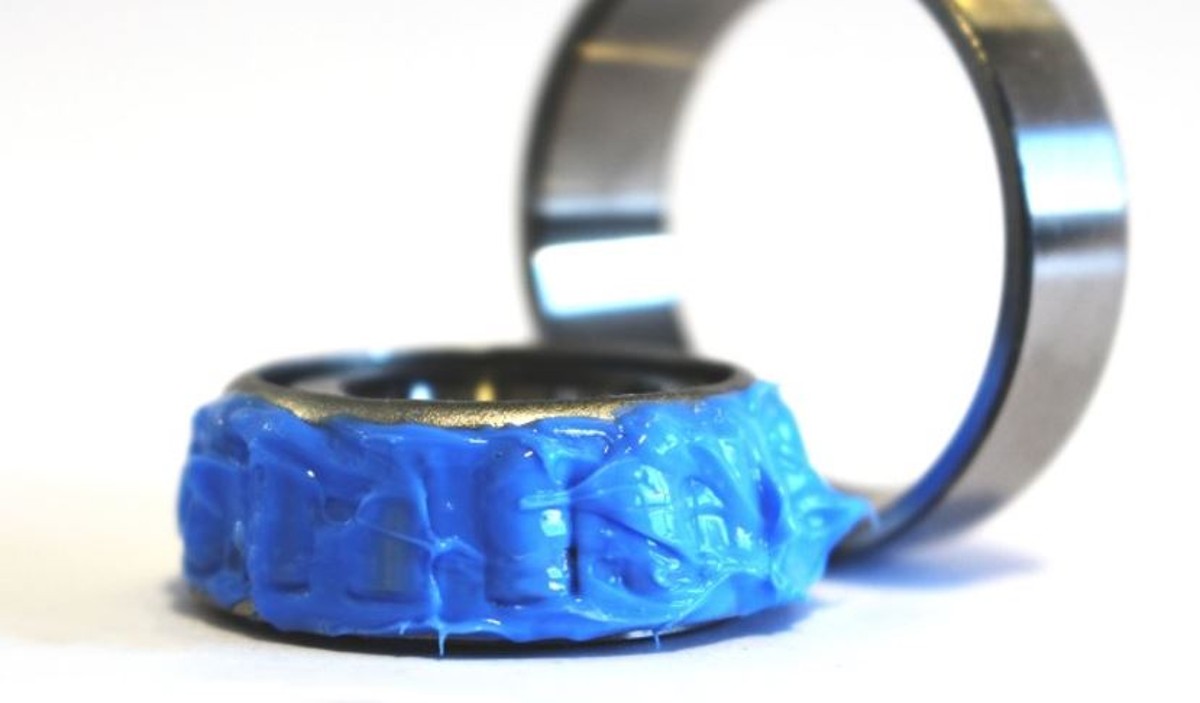

- Rolling and plain bearing greases

- Electrical contact greases

- Greases for fittings

- Food grade greases

Lubricating greases for every application

The components of lubricating greases

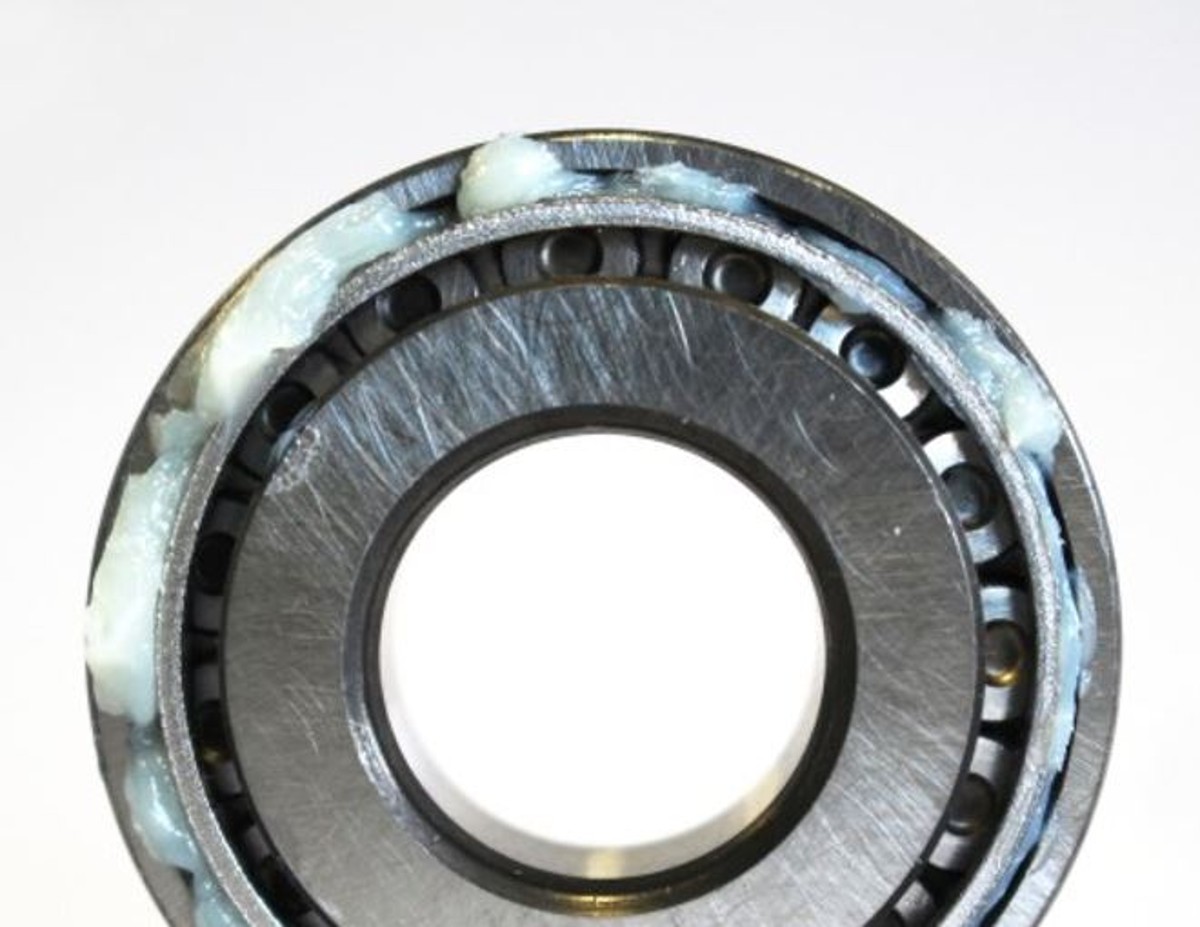

Lubricating greases are semi-liquid to solid lubricants that generally consist of the following main components:

- Base oil (about 75 percent),

- thickener (about 15 percent) and

- additives (up to 10 percent).

The lubricating performance is significantly influenced by the type of thickener. These thickeners, usually light or alkali metal soaps, surround the oil droplets and release the lubricating oil at different rates depending on temperature, time and shear. Additives also influence the application qualities of lubricating greases in terms of wear and corrosion protection, adhesion, ageing resistance and load-carrying capacity.

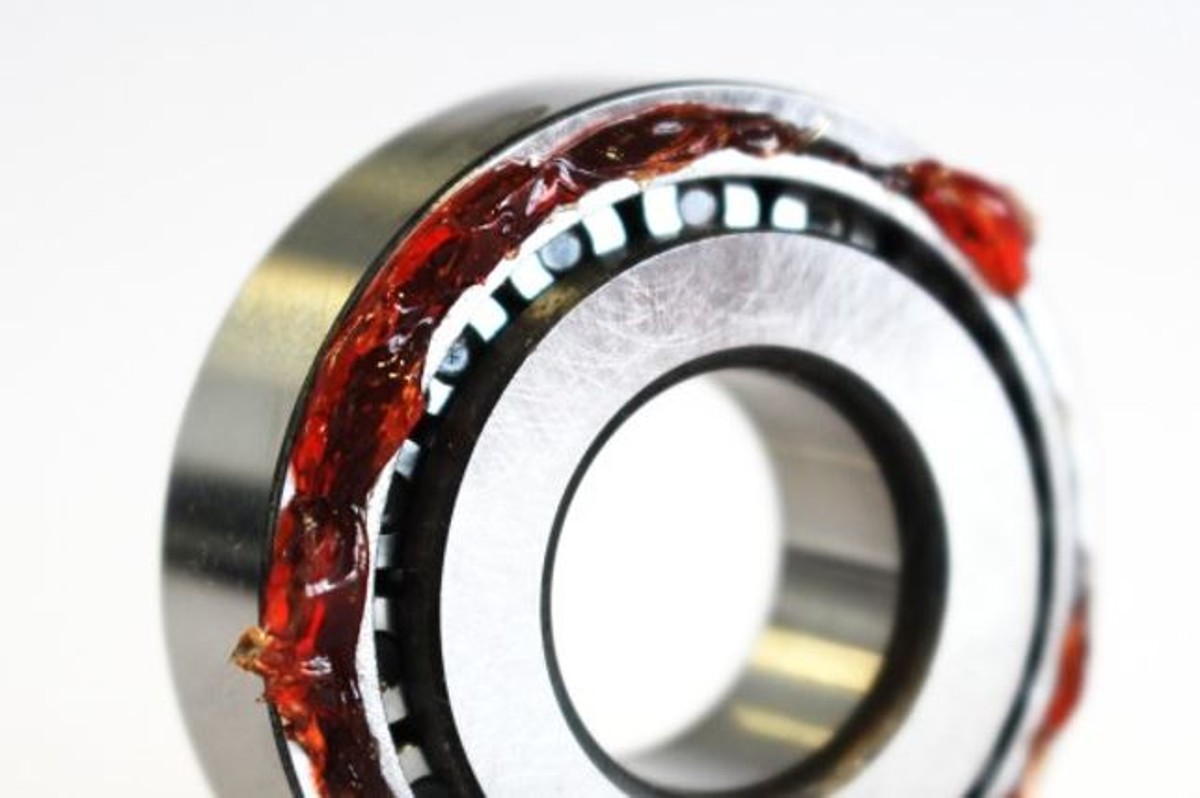

Lubrication and corrosion protection

Lubricating greases are an effective solution for protecting metal elements such as gear wheels, chains or bearing joints that are subject to particular friction and movement. In addition to lubrication, they provide effective protection against dirt and moisture. As a result, your machine metal parts are optimally protected against wear, corrosion and external influences such as splash water, humidity and dirt.